The power rating of electric motors plays a significant role in determining their performance and suitability for various applications. The power rating, typically measured in watts (W) or horsepower (HP), indicates the amount of mechanical output a motor can generate and directly impacts its capabilities, efficiency, and overall effectiveness in different tasks. Here’s how the power rating influences motor performance in different applications:

1. Determines Load Handling Capacity:

- Higher Power Rating:

- Motors with a higher power rating can handle larger or heavier loads. These are typically used in applications requiring significant mechanical output, such as large machinery, industrial equipment, and HVAC systems.

- Lower Power Rating:

- Motors with a lower power rating are suitable for applications with lighter loads, such as small household appliances, fans, and smaller electric tools.

2. Efficiency and Energy Consumption:

- Matching Power Rating to Application:

- When a motor’s power rating is appropriately matched to the application, it tends to operate more efficiently, resulting in lower energy consumption. A motor that is oversized for a task may consume more power than necessary, while an undersized motor may struggle and waste energy, leading to overheating and reduced lifespan.

- Motor Efficiency:

- Generally, motors with higher power ratings tend to be more efficient at converting electrical energy to mechanical energy, but this efficiency can vary based on the motor’s design and operating conditions.

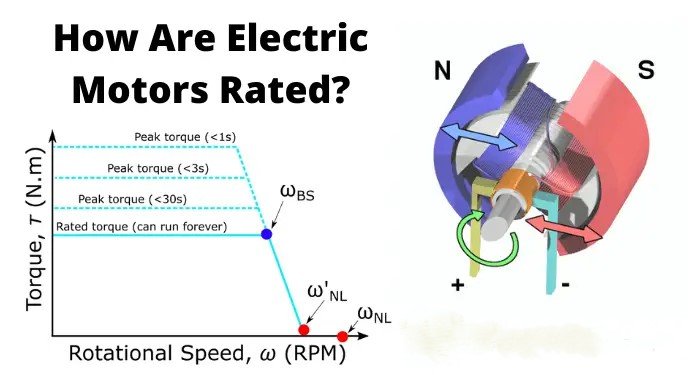

3. Impact on Speed and Torque:

- Torque and Power:

- Torque is the rotational force a motor generates. For applications requiring high torque, such as conveyors or lifting mechanisms, a higher power-rated motor may be necessary to provide the required force to move or lift heavy objects.

- Speed:

- High-power motors may operate at higher speeds, making them ideal for applications like fans or pumps that require rapid movement. However, for applications where speed control is crucial (e.g., electric vehicles or elevators), a motor’s power rating may be adjusted to optimize both speed and torque.

4. Motor Sizing and Overload Prevention:

- Proper Sizing:

- The power rating is directly related to the correct sizing of the motor for its specific task. A motor with a power rating that exceeds the requirements of the application will waste energy, while a motor with an insufficient power rating may not handle the required load, leading to performance degradation or even failure.

- Overload Protection:

- Motors with appropriate power ratings are less likely to overheat or experience mechanical failure due to overloads. Overloaded motors are prone to wear and damage, leading to costly repairs or replacements.

5. Influence on Starting and Stopping Performance:

- High-Power Motors:

- High-power motors generally require more robust starting mechanisms to handle the large inrush currents that occur during startup. Applications such as industrial machinery, where the motor needs to start under load, rely on motors with higher power ratings and proper start-up systems (e.g., soft starters or variable frequency drives).

- Low-Power Motors:

- Low-power motors, used in lighter applications like small appliances, often do not require complex starting mechanisms, and their starting currents are lower.

6. Reliability and Durability:

- Higher Power Rating:

- In demanding industrial or commercial applications, motors with higher power ratings are designed to be more durable, capable of withstanding long hours of operation under heavy load. They typically have better heat dissipation systems to prevent overheating during continuous or heavy-duty work.

- Lower Power Rating:

- Lower-power motors, while efficient for smaller tasks, may not have the same longevity under continuous operation or may not perform well under sudden or prolonged high-load conditions.

7. Cost Considerations:

- Higher Power Rating:

- Motors with higher power ratings tend to be more expensive due to their size, complexity, and material requirements. The cost increases not only in terms of the motor itself but also in terms of the power required to run it, which can make high-power motors more expensive to operate in the long run.

- Lower Power Rating:

- Smaller motors with lower power ratings are typically less expensive both in terms of initial purchase and operational costs. However, using a smaller motor for a task it is not designed for can lead to higher maintenance costs and reduced lifespan.

8. Application-Specific Examples:

- Industrial Applications:

- High-power motors are used in manufacturing plants, mining, construction, and other heavy industries. These motors drive large equipment like conveyor belts, crushers, mills, and large pumps that need to handle significant mechanical work.

- Consumer Applications:

- In consumer products, such as refrigerators, air conditioners, and washing machines, the power rating of the motor is selected based on the load requirements of the appliance. A refrigerator motor may have a power rating between 0.5 HP to 1 HP, while an air conditioning unit may need a motor with a higher power rating to drive the compressor efficiently.

- Automotive Applications:

- In electric vehicles (EVs), the motor’s power rating affects acceleration, range, and top speed. EV motors are typically rated in kilowatts (kW), and high-power motors are necessary for applications like long-distance travel or performance vehicles.

- HVAC Systems:

- HVAC systems, such as large air conditioning units, require high-power motors for compressors, fans, and pumps to maintain optimal airflow and temperature control in commercial or industrial buildings.

Conclusion:

The power rating of electric motors is fundamental in determining their performance, efficiency, and suitability for various applications. A properly selected motor ensures optimal operation, energy efficiency, and cost-effectiveness while preventing issues such as overheating, underperformance, or premature failure. Whether in consumer products, industrial machinery, or automotive systems, matching the motor’s power rating to its application requirements is crucial for maximizing performance and longevity.

Hashtags

#MotorPowerRating #ElectricMotorPower #MotorPerformance #PowerRatedMotors #MotorPowerVsPerformance #MotorTorqueAndPower #OptimizedMotorPerformance #MotorPowerEfficiency #PowerRatedElectricMotors #PerformanceDrivenByPower #MotorTorque #HighTorqueMotors #PowerForHighTorque #PowerfulElectricMotors #MotorTorqueAndSpeed #PowerToTorqueConversion #MotorsForHighTorqueApplications #MotorTorqueAndPerformance #TorquePerformanceWithPower #PowerAndTorqueBalance #MotorSelection #ChoosingTheRightMotor #MotorPowerForApplications #ApplicationBasedMotorSelection #MotorPowerForIndustrialUse