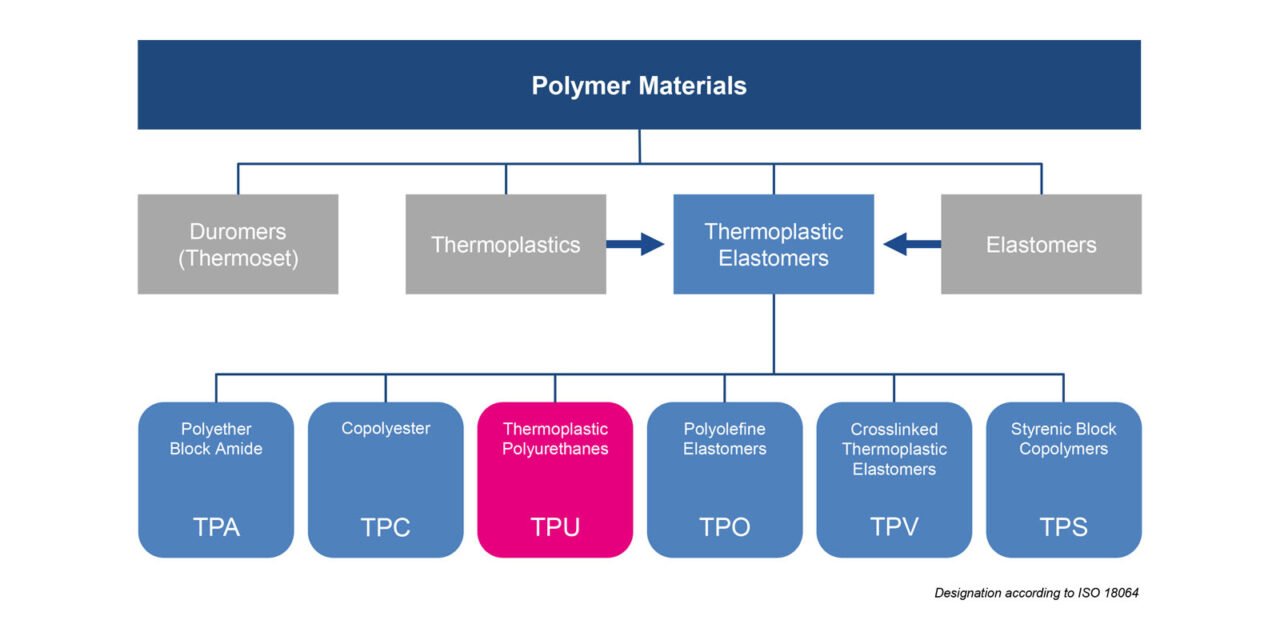

Thermoplastic Polyurethane (TPU) is a versatile material used across multiple industries due to its ability to combine flexibility, durability, and chemical resistance. Manufacturers modify TPU formulations based on the requirements of each industry. The variations in TPU depend on the type of polyol, isocyanate, and additives used in its production. Below is an overview of different TPU types and their applications in various industries.

1. Polyether-Based TPU

Industries and Applications

- Medical and Healthcare: Used in medical tubing, catheters, and prosthetics due to its flexibility, biocompatibility, and resistance to hydrolysis.

- Automotive: Found in seals, fuel hoses, and interior components because of its resistance to oil and chemicals.

- Footwear: Applied in shoe soles and midsoles for its elasticity and impact absorption.

- Electronics: Used in wearable devices and flexible cables due to its softness and durability.

Key Properties

- High hydrolysis resistance, making it suitable for moisture-exposed applications.

- Good microbial resistance, ensuring longevity in medical and outdoor applications.

- High elasticity and impact resistance, providing comfort in footwear and wearables.

2. Polyester-Based TPU

Industries and Applications

- Industrial Manufacturing: Used in conveyor belts, caster wheels, and protective coatings due to its abrasion resistance.

- Automotive: Common in drive belts, dashboard coatings, and oil-resistant gaskets.

- Sporting Goods: Found in inflatable boats, protective padding, and performance gear for its strength.

- Consumer Goods: Applied in durable smartphone cases and luggage materials.

Key Properties

- High abrasion and wear resistance, making it ideal for heavy-duty applications.

- Excellent chemical resistance, especially to oils, fuels, and solvents.

- Superior mechanical strength, allowing for use in high-stress environments.

3. Polycarbonate-Based TPU

Industries and Applications

- Electronics and Wearables: Used in protective casings for mobile devices and laptops due to its impact resistance.

- Automotive: Applied in lightweight structural parts and dashboards for improved durability.

- Aerospace: Used in flexible aircraft components due to its high temperature resistance.

Key Properties

- Superior impact strength, making it resistant to cracks and deformation.

- High temperature stability, suitable for extreme environments.

- Long-term durability, maintaining integrity over extended use.

4. Aliphatic TPU

Industries and Applications

- Fashion and Footwear: Used in transparent shoe soles and accessories due to its clarity and UV stability.

- Automotive: Applied in transparent protective coatings for headlights and windshields.

- Medical: Found in medical tubing and devices that require clarity and biocompatibility.

Key Properties

- UV and weather resistance, preventing yellowing over time.

- High optical clarity, allowing for use in transparent applications.

- Non-yellowing properties, making it suitable for outdoor exposure.

5. Flame-Retardant TPU

Industries and Applications

- Electronics and Electrical: Used in insulating cables, connectors, and circuit board coatings to prevent fire hazards.

- Construction: Applied in fire-resistant coatings for walls and floors.

- Automotive: Found in wire harnesses and protective coatings to enhance fire safety.

Key Properties

- Enhanced flame resistance, reducing fire risks in sensitive applications.

- Maintains flexibility while providing fire protection.

- Compliant with fire safety regulations for industrial and residential use.

6. Conductive and Anti-Static TPU

Industries and Applications

- Electronics and Semiconductors: Used in electrostatic discharge (ESD) protective covers and flooring.

- Aerospace: Applied in aircraft components that require controlled electrical conductivity.

- Industrial Machinery: Used in anti-static conveyor belts and protective equipment.

Key Properties

- Dissipates static electricity, preventing electrical hazards.

- Maintains mechanical strength while providing electrical conductivity.

- Used in environments where electrostatic discharge control is critical.

7. Biodegradable and Bio-Based TPU

Industries and Applications

- Sustainable Fashion and Footwear: Used in eco-friendly shoe soles and apparel accessories.

- Medical: Applied in biodegradable medical implants and temporary medical devices.

- Packaging: Found in flexible, compostable packaging films.

Key Properties

- Derived from renewable sources, reducing environmental impact.

- Biodegradable in controlled conditions, making it ideal for sustainable applications.

- Retains the mechanical properties of traditional TPU while being eco-friendly.

8. TPU for 3D Printing

Industries and Applications

- Prototyping and Custom Manufacturing: Used for creating flexible, durable prototypes.

- Medical Devices: Applied in customized prosthetics and orthopedic supports.

- Automotive: Found in flexible vehicle components and personalized accessories.

Key Properties

- High flexibility and toughness, allowing for detailed 3D-printed parts.

- Excellent layer adhesion, ensuring structural integrity.

- Compatible with multiple 3D printing technologies, including fused filament fabrication.

Conclusion

Different types of TPU are formulated to meet the unique demands of various industries. Polyether-based TPU is widely used for moisture-resistant applications, while polyester-based TPU is preferred for high-wear environments. Polycarbonate-based TPU offers superior impact resistance, and aliphatic TPU is ideal for transparent and UV-resistant applications. Flame-retardant and anti-static TPU enhance safety in electronics and construction, while biodegradable TPU supports sustainability. TPU for 3D printing continues to expand possibilities in customized manufacturing.

Hahstags

#TPUTypes #IndustrialTPU #TPUApplications #HighPerformanceTPU #FlexibleMaterials #WearResistant #TPUManufacturing #ThermoplasticElastomers #SmartPolymers #AutomotiveTPU #FootwearTPU #MedicalTPU #ElectronicsTPU #TextileTPU #SustainableTPU #BioBasedTPU #EcoFriendlyPlastics #RecyclableMaterials #TPUInnovation #CustomPolymers #PolymerScience #MaterialInnovation #AdvancedMaterials #TPUResearch #GreenMaterials