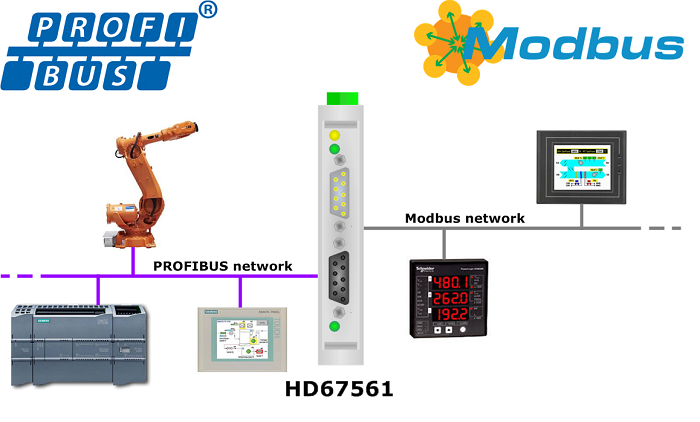

Communication protocols like Modbus and Profibus are widely used in industrial electronics to facilitate data exchange between various devices, such as sensors, controllers, and actuators, within industrial automation systems. They ensure seamless communication, real-time monitoring, and control across complex industrial processes.

Modbus

- Overview: Modbus is an open, serial communication protocol commonly used in industrial control systems for data exchange. It is simple, reliable, and widely supported by various industrial devices.

- Function: Modbus allows devices (like PLCs, sensors, and controllers) to communicate over a serial line (RS-232, RS-485) or Ethernet (Modbus TCP/IP). It enables the transmission of data such as sensor readings, status updates, and control commands between devices in an industrial network.

- Use: It is typically used for remote monitoring and control in industries such as manufacturing, oil and gas, and water treatment. For example, a PLC might use Modbus to communicate with remote sensors and actuators, collecting data and issuing control commands based on process conditions.

Profibus

- Overview: Profibus (Process Field Bus) is a family of communication protocols used in industrial automation, specifically for connecting controllers and field devices like sensors, actuators, and drives. It is more advanced than Modbus and offers higher performance for complex systems.

- Function: Profibus operates on both serial and industrial Ethernet networks and supports real-time communication. Profibus DP (Decentralized Periphery) is often used for high-speed communication in control loops, while Profibus PA (Process Automation) is tailored for process control applications in industries like chemicals and pharmaceuticals.

- Use: Profibus is used in process control systems to connect PLCs, remote I/O devices, and sensors in a factory or plant. For instance, in a production line, Profibus can enable quick communication between a PLC and multiple distributed field devices to ensure coordinated operations.

Key Differences

- Speed and Complexity: Profibus is typically faster and more suitable for complex, high-speed applications compared to Modbus, which is simpler and more commonly used for basic control and monitoring tasks.

- Real-Time Communication: Profibus supports real-time communication for time-sensitive control, while Modbus is typically used for less time-critical applications.

- Network Topology: Modbus can be used over serial and Ethernet networks, while Profibus is primarily designed for industrial networks and more complex topologies, including bus and star configurations.

Both Modbus and Profibus are essential communication protocols in industrial electronics, enabling effective data exchange between devices. Modbus is favored for simpler, cost-effective systems, while Profibus is preferred for high-performance, complex systems that require faster data transfer and real-time control.