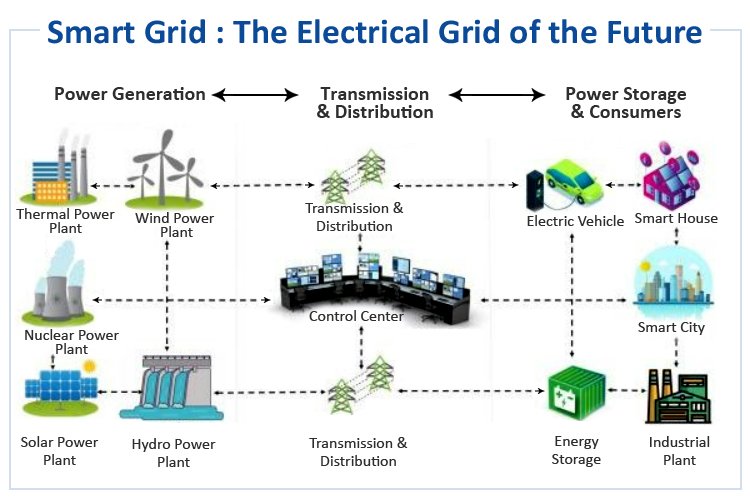

Industrial electronics play a pivotal role in the development and operation of smart grids, which are advanced electrical grids that use digital communication, automation, and control technologies to enhance the efficiency, reliability, and sustainability of electricity distribution. Here’s how industrial electronics enable the development of smart grids:

1. Advanced Metering Infrastructure (AMI)

- Smart Meters: Industrial electronics in smart meters allow for real-time monitoring of energy consumption at the consumer level. These meters send data back to the utility provider, enabling accurate billing, demand forecasting, and load management. Smart meters also provide consumers with detailed information on their energy usage, helping them make informed decisions about consumption.

- Data Collection and Communication: Smart meters and other metering devices use communication protocols like Modbus, Zigbee, and Wi-Fi to transmit data between meters, substations, and utility control centers. This allows utilities to manage grid operations and respond dynamically to demand and supply fluctuations.

2. Grid Automation and Control

- Programmable Logic Controllers (PLCs): PLCs and remote terminal units (RTUs) control and automate various components of the grid, such as circuit breakers, switches, and transformers. These devices help detect faults, reroute power, and optimize grid performance in real time.

- SCADA Systems: Industrial electronic systems like SCADA (Supervisory Control and Data Acquisition) play a central role in smart grid operations. SCADA systems monitor and control the grid by providing real-time visibility of power flow, voltage levels, and equipment status. This allows for rapid response to faults and ensures continuous power supply.

3. Distributed Energy Resource (DER) Integration

- Inverters and Power Electronics: Power electronics devices like inverters are used to convert the output from renewable energy sources (e.g., solar panels, wind turbines) into usable electricity that can be fed into the grid. Industrial electronics ensure that the integration of these renewable energy sources is seamless and that the grid operates efficiently even with varying energy inputs.

- Energy Storage Systems: Industrial electronic devices control and manage energy storage systems (such as batteries) that store excess energy produced during peak renewable generation times. These systems help balance supply and demand, providing backup power during outages or when renewable energy generation is low.

4. Demand Response and Load Management

- Smart Appliances: Industrial electronics enable the development of smart appliances that communicate with the grid to adjust their power usage based on demand-response signals. For example, air conditioners, water heaters, and electric vehicle chargers can automatically adjust their operation during peak hours to help reduce grid stress.

- Automated Load Control: Industrial electronics, such as smart thermostats and controllers, can manage energy consumption in real-time based on pricing signals or grid conditions. This helps balance demand with available supply and reduces the need for fossil fuel-based power generation during peak periods.

5. Communication Networks and Data Management

- Industrial Communication Protocols: Industrial electronics enable communication between grid components using standard protocols such as Ethernet/IP, Modbus, DNP3, and IEC 61850. These communication networks enable the efficient exchange of data between grid assets and control centers, ensuring synchronized grid operations.

- Big Data and Analytics: Industrial electronics in smart grids generate vast amounts of data from various devices (smart meters, sensors, and controllers). Data analytics tools process this data to optimize grid operations, predict failures, and improve asset management. Predictive analytics help utilities anticipate maintenance needs and improve decision-making.

6. Fault Detection and Self-Healing

- Sensors and Smart Relays: Industrial electronics, such as smart sensors and protective relays, monitor grid conditions and detect faults (e.g., short circuits, voltage irregularities). These devices can automatically isolate faults, reroute power, and restore service with minimal human intervention, making the grid more resilient.

- Self-Healing Capabilities: Through the use of intelligent controllers and automated switching devices, smart grids can self-heal by quickly detecting and responding to faults. When a fault occurs, the system automatically isolates the affected section and reroutes power to ensure minimal disruption to consumers.

7. Grid Security and Cybersecurity

- Encryption and Secure Communication: Industrial electronics are critical for securing the communication between grid components and preventing cyber threats. Advanced encryption and authentication protocols ensure that data transmitted between smart meters, sensors, and control systems is protected from unauthorized access or tampering.

- Intrusion Detection Systems: Industrial electronics also play a role in monitoring for cyber threats and ensuring the integrity of the smart grid’s operation. Intrusion detection systems and firewalls help safeguard the grid from malicious attacks that could compromise power generation, distribution, or user data.

8. Power Quality Monitoring

- Harmonic Filters and Condition Monitoring: Industrial electronics are used to monitor and maintain power quality, ensuring that electrical signals are free from distortions, harmonics, and voltage spikes. This is essential for the proper functioning of sensitive equipment, such as computers and medical devices.

- Voltage Regulation: Industrial electronics help manage voltage fluctuations across the grid by using dynamic voltage regulators and capacitor banks. This ensures stable power delivery and protects equipment from overvoltage or undervoltage conditions.

9. Integration with Electric Vehicles (EVs)

- EV Charging Stations: Industrial electronics in EV charging stations enable smart charging by communicating with the grid to adjust charging times based on grid demand. During off-peak hours, EVs can be charged, helping balance grid load.

- Vehicle-to-Grid (V2G) Technology: V2G technology allows EVs to send excess power back to the grid during peak demand periods. Industrial electronics in both vehicles and charging infrastructure facilitate this bidirectional flow of energy, enhancing grid stability.

Industrial electronics enable the development of smart grids by integrating advanced communication, automation, and control technologies that improve grid efficiency, reliability, and sustainability.