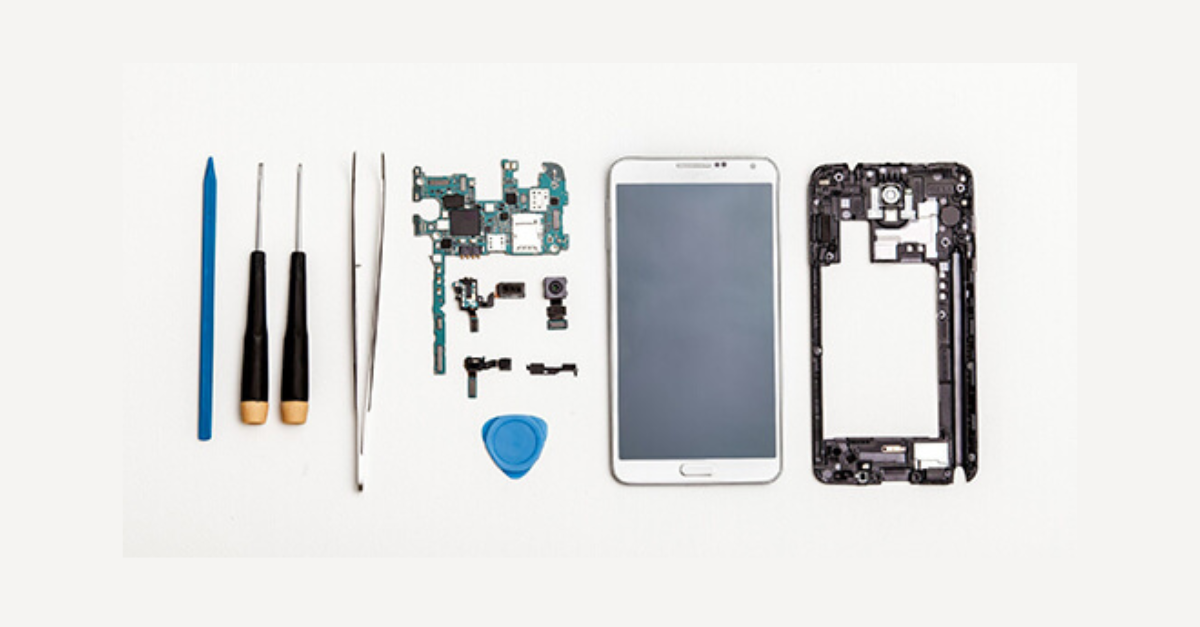

Manufacturers ensure the quality and reliability of mobile phone components through a combination of rigorous testing, quality control processes, and supplier management practices. These steps are crucial to delivering high-performance, durable, and user-friendly devices. Here’s an overview of the key strategies employed to ensure the quality and reliability of mobile phone components:

1. Supplier Selection and Management:

- Stringent Supplier Criteria: Mobile phone manufacturers establish strict criteria for selecting suppliers of components, such as semiconductors, displays, batteries, cameras, and sensors. Suppliers are carefully vetted for their ability to meet technical specifications, quality standards, and delivery timelines.

- Collaboration with Trusted Suppliers: Manufacturers often form long-term partnerships with trusted suppliers that have proven track records in providing high-quality components. Regular audits and performance reviews are conducted to ensure suppliers maintain consistent quality levels.

2. Component Testing:

- Reliability Testing: Manufacturers conduct thorough reliability testing on individual components to ensure they meet or exceed performance expectations under real-world conditions. These tests include:

- Temperature and Humidity Tests: Components are exposed to extreme temperatures and humidity levels to simulate the range of environmental conditions a mobile phone may face during its lifespan.

- Vibration and Shock Testing: Components are subjected to vibrations and shock forces to evaluate their durability, especially in the case of mechanical parts like buttons, screens, and connectors.

- Drop and Impact Tests: Mobile phones are subjected to drop tests to assess the impact resistance of components and to minimize damage during accidental falls.

- Battery Life and Charging Cycles: Batteries are tested for their longevity, charge retention, and performance over multiple charge cycles to ensure they meet the expected lifespan.

- Thermal Performance: Components are tested for heat resistance and their ability to operate efficiently without overheating, especially processors, batteries, and displays.

3. Quality Control in Manufacturing:

- Automated Inspection: Advanced automated optical inspection (AOI) systems are used during the manufacturing process to detect defects and imperfections in components such as screens, circuit boards, and chips. These systems can detect micro-level defects that are difficult for the human eye to spot.

- Assembly Line Monitoring: Throughout the assembly process, quality control technicians and robots continuously monitor the production line for defects. This includes checking for correct component placement, soldering quality, and other assembly issues.

- Real-time Data Analytics: Manufacturers use real-time data collection and analytics to monitor the quality of components and subassemblies on the production floor. Statistical process control (SPC) techniques are used to identify any quality issues and correct them immediately.

4. Stress Testing and Performance Evaluation:

- Functional Testing: Once the phone is assembled, it undergoes functional testing to ensure all components work as intended. This includes testing the display, touch functionality, sensors, camera, Wi-Fi, Bluetooth, speakers, and more.

- Performance Benchmarks: Mobile phones are tested for performance, including processing power, graphics performance, and multitasking capabilities. Benchmarking tools and software are used to measure how well the phone performs under stress, ensuring it meets the expected standards for gaming, app usage, and daily tasks.

5. Environmental Testing:

- Water and Dust Resistance: Many modern mobile phones are designed with IP ratings (Ingress Protection) to ensure they are resistant to water and dust. Manufacturers test components and final devices for water resistance by submerging them in water or exposing them to water sprays.

- Corrosion Resistance: Components, especially those in contact with moisture (such as connectors and charging ports), are tested for corrosion resistance to ensure they maintain performance over time.

6. Component Authentication and Anti-Counterfeit Measures:

- Authentication Systems: To ensure the quality of components, manufacturers employ authentication technologies to verify the authenticity of the parts used in the phones. This helps to protect against counterfeit parts that may not meet the required quality and safety standards.

- Unique Serial Numbers: Many mobile phone manufacturers assign unique serial numbers to each device and its components (such as the processor or battery). This makes it easier to trace the origin of components and detect counterfeit products in the supply chain.

7. User Testing and Field Trials:

- Beta Testing and Feedback: Before a mobile phone model is launched, it undergoes extensive beta testing, where a selected group of users test the device in real-world scenarios. Their feedback helps manufacturers identify any functional or usability issues that were not detected during lab testing.

- Stress Testing by Users: In addition to lab testing, manufacturers observe how devices perform under actual usage patterns, such as heavy app usage, gaming, and multitasking, to identify potential weaknesses.

8. Adherence to Industry Standards and Certifications:

- Compliance with Standards: Mobile phone manufacturers adhere to international quality standards, such as ISO 9001 (quality management systems) and ISO 14001 (environmental management systems). These certifications ensure that the production process and components meet established global benchmarks.

- Safety Certifications: Manufacturers also ensure that mobile phones meet safety standards, such as those set by UL (Underwriters Laboratories) or CE (Conformité Européenne), which demonstrate compliance with electrical safety, electromagnetic compatibility (EMC), and other important safety factors.

9. End-of-Life Testing:

- Endurance Over Time: Manufacturers also test the phone for end-of-life performance to ensure that it remains reliable even as it ages. This includes evaluating battery degradation over time, screen burn-in (for OLED displays), and component aging.

10. Continuous Improvement and Feedback Loops:

- Continuous Monitoring: Manufacturers use a feedback loop that includes customer reviews, warranty claims, and performance data from the field to continuously improve the design and quality of components. Data gathered after the product’s launch helps to identify areas for improvement in future models.

- Research and Development: Ongoing research and development (R&D) help manufacturers stay ahead of emerging trends and technologies, ensuring that the components they use in mobile phones remain cutting-edge and reliable.

Conclusion:

By combining rigorous testing, robust quality control measures, advanced manufacturing technologies, and continuous improvement practices, mobile phone manufacturers ensure that their components meet high standards for performance, reliability, and safety. This holistic approach helps them produce mobile phones that can withstand real-world use, maintain high functionality over time, and meet customer expectations.

Hashtags

#MobilePhoneQuality #QualityControlInManufacturing #PhoneComponentTesting #QualityAssurance #MobileDeviceTesting #QualityChecks #TestedForReliability #QualityStandards #ComponentTestTech #ReliabilityTesting #ComponentSourcing #MobilePhoneComponents #SupplierQuality #ComponentReliability #MobileComponentManufacturing #SmartphoneComponentSuppliers #SourcingHighQualityParts #SupplyChainOptimization #MobilePartsQuality #TrustedMobileComponents #MobileCertification #ComponentCompliance #QualityCertification #StandardsInManufacturing #CECertification #ISOQualityStandards #IndustryCertification #CertifiedComponents #GlobalStandards #MobilePhoneCompliance #HighQualityMaterials