As industries continue to embrace automation to enhance productivity, improve accuracy, and reduce human error, there is a growing demand for testing and measurement equipment to ensure the seamless functioning of automated systems. Automation in manufacturing, logistics, and various industrial processes has significantly transformed the way operations are conducted, but it has also led to an increased reliance on precise measurements and quality control. This has created a surge in the need for advanced tools and systems capable of accurately testing and measuring robotics, sensors, actuators, controllers, and other automated components.

The automated systems that are becoming commonplace across industries, particularly in the electronics, automotive, and consumer goods sectors, rely heavily on real-time data monitoring, quality control, and system diagnostics to ensure smooth operations. The need for high-performance testing equipment has never been more critical, as these systems are complex and require constant monitoring to ensure they perform at optimal levels. Measurement tools such as calibration instruments, sensors, meters, and control systems are essential to validate the precision, accuracy, and reliability of automated machines, especially in high-stakes sectors like pharmaceuticals, automotive manufacturing, and electronics production.

The increasing integration of Industry 4.0 technologies such as the Internet of Things (IoT), AI-driven systems, and big data analytics into automated workflows further elevates the need for testing and measurement solutions that can handle vast amounts of data and ensure the efficiency and safety of connected systems. As automated operations become more intelligent and interconnected, the testing and measurement equipment must also evolve to handle real-time diagnostics, predictive maintenance, and performance verification.

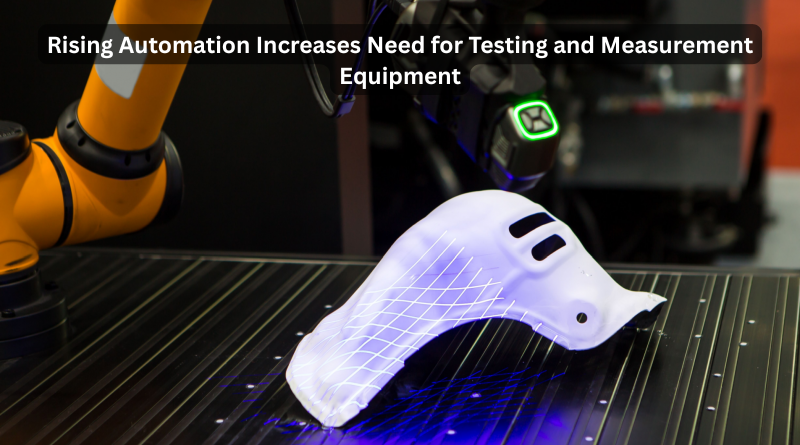

Furthermore, as industries adopt advanced robotics and machine learning for more sophisticated operations, high-precision measurement equipment becomes necessary to guarantee that robotic systems are performing with the exactitude required. Whether it’s for calibrating robotic arms, ensuring the correct alignment of machinery, or validating the integrity of sensors and control systems, these tools are indispensable to avoid downtime, improve operational efficiency, and maintain product quality.

The increased reliance on automated systems is also driving innovation in the testing and measurement sector, with companies offering smart solutions that integrate with automated systems for continuous, real-time monitoring. These solutions not only help in testing but also facilitate ongoing data collection, system optimization, and performance forecasting. As automation continues to evolve, the demand for reliable, high-precision testing equipment will only grow, positioning it as a key enabler for the success of modern industrial operations.In summary, the rise in automation across various sectors is driving an urgent need for testing and measurement equipment that ensures the optimal performance, safety, and efficiency of automated systems. As technology advances, the demand for these tools will continue to expand, fostering innovation and enabling industries to maintain competitive advantage in an increasingly automated world.