Cable management systems are essential in industrial applications for ensuring the safe, organized, and efficient routing of electrical cables and wires. These systems help protect cables from physical damage, reduce the risk of accidents, improve system reliability, and contribute to the overall performance and longevity of industrial electrical systems. Here’s why cable management is critical in industrial settings:

1. Safety

- Preventing Hazards: Poorly managed cables can create tripping hazards, cause electrical shorts, or be exposed to mechanical stress, leading to accidents or fires. Cable management systems keep cables organized and out of high-traffic areas, reducing the risk of such hazards.

- Fire Prevention: Cables that are improperly routed or exposed to heat and friction may overheat, which can result in insulation degradation or sparks. A cable management system ensures that cables are routed in a way that prevents excessive wear and reduces the risk of fires.

- Electrical Hazards: By providing adequate protection and insulation, cable management systems reduce the likelihood of accidental contact with live wires, which can lead to electrical shocks.

2. Organization and Efficiency

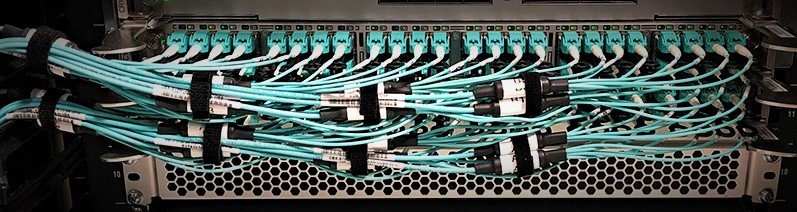

- Streamlined Routing: Industrial applications often involve complex systems with numerous cables. Cable management systems, such as cable trays, conduits, and raceways, help streamline the routing of cables, making it easier to follow their path, troubleshoot issues, or expand the system in the future.

- Space Optimization: Properly organized cables take up less space, making the workplace more efficient and allowing for easier access to electrical systems. This is especially important in cramped or high-density environments like industrial plants or data centers.

- Future Expansion: A well-organized cable system can easily accommodate future upgrades or additions, making it simpler to add new cables or modify existing ones without disrupting operations.

3. Protection and Longevity

- Physical Protection: Cables are vulnerable to damage from abrasion, impact, moisture, dust, and chemicals in industrial environments. Cable management systems provide protective channels and enclosures to safeguard cables from such damage, extending their lifespan and reducing the risk of costly repairs.

- Preventing Cable Strain: Cables subjected to excessive bending, pulling, or twisting can experience strain, which may result in internal damage or failure. Cable management systems ensure that cables are properly supported and avoid mechanical stress.

- Environmental Protection: In industries where cables may be exposed to extreme temperatures, chemicals, or moisture, cable management systems protect cables by using appropriate materials like insulated trays, coated cables, and weather-resistant conduits.

4. Improved Reliability and Performance

- Minimizing Downtime: A well-managed cable system is less likely to experience failure due to wear or disconnection, leading to reduced downtime and more reliable operations.

- Signal Integrity: In industries relying on data transmission, such as telecommunications or automation, cable management systems help maintain the integrity of electrical signals by preventing interference from other cables, reducing the risk of data loss or signal degradation.

- Reduced Power Loss: Properly managed cables ensure that electrical power flows efficiently with minimal loss. By ensuring that cables are routed correctly and securely, power loss due to unnecessary resistance or improper connections can be minimized.

5. Compliance with Standards and Regulations

- Code Compliance: Industrial electrical systems must adhere to local and international standards (e.g., NEC, IEC). Cable management systems help ensure compliance by providing proper routing, separation of cables, and protection against environmental factors, which are typically required by electrical codes.

- Inspection and Maintenance: Proper cable management makes it easier for technicians to inspect the system for damage, wear, or faults. It also facilitates scheduled maintenance and quick troubleshooting, as cables are clearly labeled and organized.

6. Aesthetic and Operational Clarity

- Neatness and Clarity: In industrial settings, particularly in large plants or factories, an organized cable system contributes to a cleaner, more professional environment. This makes it easier for workers to identify specific cables and systems, improving workflow and operational clarity.

- Visual Inspection: Organized cables are easier to visually inspect during routine checks, helping to identify potential issues early before they lead to significant problems.

7. Cost Efficiency

- Reducing Damage Costs: By protecting cables from physical damage, cable management systems can prevent costly repairs or replacements. They also minimize the need for downtime, which can be expensive in a production environment.

- Minimizing Energy Loss: Properly routed cables reduce the chances of electrical faults, such as short circuits or resistance-related losses, which can waste energy and increase operational costs.

- Simplifying Installation: A well-planned cable management system makes it easier to install cables, reducing labor costs during the installation phase.

8. Types of Cable Management Systems Used in Industrial Applications

- Cable Trays: Support cables in a horizontal or vertical layout, providing a safe and organized route for multiple cables. They are typically made from metal or plastic and are used in factories, power plants, and data centers.

- Conduits: Tubes that house and protect cables from external damage and environmental factors. Conduits can be made of metal (e.g., steel) or flexible plastic.

- Cable Raceways: Similar to trays, raceways offer a closed system for cable routing and can be used for both power and data cables.

- Cable Ties and Clips: Used for bundling and securing cables together in a neat and organized manner. They ensure that cables do not move or get damaged.

- Junction Boxes and Enclosures: Used to protect electrical connections and splices between cables, ensuring that they are safely housed and accessible for maintenance.

Conclusion:

Cable management systems play a vital role in the overall efficiency, safety, and longevity of electrical systems in industrial applications. They provide protection against physical damage, ensure proper system organization, improve safety by reducing hazards, and help maintain the integrity and reliability of electrical systems. In addition, they support compliance with industry regulations, contribute to cost savings, and make maintenance and future upgrades more straightforward. By investing in effective cable management, industrial operations can ensure smoother and safer operations, lower downtime, and a more streamlined electrical system.

Hashtags

#CableSafety #CableManagementForSafety #SafeElectricalSystems #OrganizedCabling #ElectricalSafetyStandards #HazardFreeCabling #SafetyInWiringSystems #SafeCableRouting #AvoidCableHazards #CableProtection #EfficiencyInIndustrialEnvironments #EfficientCableManagement #IndustrialCableSolutions #OptimizedWiringSystems #EfficientPowerDistribution #CableOrganizationForEfficiency #IndustrialCablingEfficiency #CableRoutingSolutions #StreamlinedCabling #MaximizedCableEfficiency #ImprovedWiringEfficiency #PreventDowntime #CableMaintenanceManagement #ReduceCableFailures #CableManagementForReliability #MinimizeWiringIssues #PreventiveCableCare #CableManagementMaintenance #WiringTroubleshooting #LessCableDowntime #TroubleFreeCabling #OrganizedCables #SpaceSavingCabling #CableOrganizationSystems #OptimizedWiringSpace #ClutterFreeWiring #IndustrialCableOrganization #CableStorageSolutions #CableRackSystems