Industrial electronic devices play a critical role in process control across various industries, including manufacturing, energy, chemicals, pharmaceuticals, and food processing. These devices help monitor, control, and automate complex industrial processes to improve efficiency, safety, reliability, and product quality. Here’s how industrial electronic devices contribute to process control:

1. Automation and Control

- Programmable Logic Controllers (PLCs): PLCs are central to industrial automation, serving as the “brains” of process control systems. They receive input from sensors, process that data, and trigger appropriate outputs to control machinery and equipment. For example, in a manufacturing plant, PLCs manage conveyor belts, robotic arms, and assembly lines to maintain continuous production.

- Distributed Control Systems (DCS): DCS are used for complex, large-scale processes, especially in industries like oil and gas, chemical, and power generation. They provide real-time monitoring and control, offering high reliability, flexibility, and scalability in managing multiple process variables across different locations within a plant.

2. Monitoring and Data Acquisition

- Sensors and Transducers: Industrial sensors (temperature, pressure, flow, level, etc.) are essential for measuring physical variables in a process. These sensors continuously monitor system conditions and send data to control systems for analysis. The data helps operators track process performance, detect anomalies, and make informed decisions.

- Data Acquisition Systems (DAQ): DAQ systems collect and process data from sensors and transmit it to control systems for further analysis. This data can be used for process optimization, predictive maintenance, and troubleshooting, helping improve decision-making and reducing downtime.

3. Real-Time Process Optimization

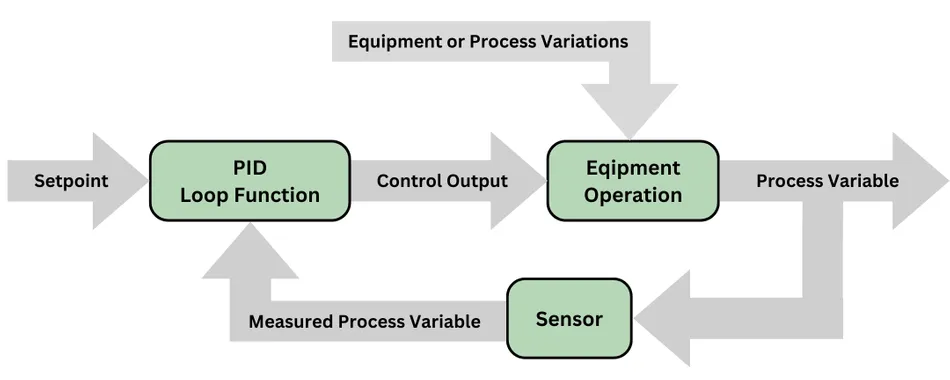

- Control Loops: In process control, electronic devices are integral to implementing control loops such as PID (Proportional, Integral, Derivative) controllers. These devices adjust parameters (e.g., temperature, pressure, speed) in real time based on feedback from sensors, ensuring that processes operate within the desired range and achieving optimal performance.

- Advanced Process Control (APC): APC techniques, including model-based control and predictive control, are used to optimize complex industrial processes. These systems use mathematical models to anticipate process changes and adjust control variables proactively, reducing inefficiencies and improving output quality.

4. Safety and Protection

- Safety Instrumented Systems (SIS): Industrial electronic devices are crucial for maintaining safety in hazardous environments. SIS are designed to detect dangerous conditions (e.g., gas leaks, temperature spikes) and automatically shut down or adjust processes to prevent accidents. These systems ensure that safety standards and regulations are met, protecting workers and equipment.

- Emergency Shutdown Systems (ESD): ESD systems are used in critical processes to immediately halt operations in case of an emergency. These systems are integrated with industrial control systems to activate valves, pumps, and other equipment to prevent further damage or hazards.

5. Communication and Integration

- Industrial Networks: Industrial communication networks like Modbus, Ethernet/IP, and PROFIBUS allow seamless integration of electronic devices and systems, enabling real-time data exchange between sensors, controllers, and operators. This interconnectedness improves coordination and responsiveness across all levels of the operation.

- Supervisory Control and Data Acquisition (SCADA): SCADA systems provide centralized monitoring and control over industrial processes. SCADA collects data from sensors, PLCs, and other devices, allowing operators to visualize process conditions, make decisions, and send control commands remotely. SCADA enhances decision-making by providing operators with a comprehensive view of plant operations.

6. Predictive Maintenance

- Condition Monitoring: Industrial electronic devices, such as vibration sensors, thermography cameras, and oil analysis tools, are used to monitor the health of machinery and equipment. By analyzing data trends, operators can identify potential failures before they occur, minimizing unplanned downtime and extending the life of assets.

- Maintenance Scheduling: With the help of process control systems and data analytics, maintenance tasks can be scheduled based on the actual condition of equipment rather than relying on fixed intervals. This results in cost savings and enhanced reliability.

7. Energy Efficiency

- Energy Management Systems (EMS): EMS use industrial electronic devices to monitor and control energy consumption across processes. These systems optimize energy usage by adjusting equipment operation based on demand, production schedules, and external conditions, helping reduce waste and lower operational costs.

- Variable Frequency Drives (VFDs): VFDs control the speed of motors based on real-time requirements, ensuring energy is used efficiently. For instance, in a pump or fan system, VFDs adjust motor speed to match the desired flow rate, leading to energy savings without compromising performance.

8. Quality Control

- Inline Process Inspection: Electronic devices such as vision systems, sensors, and automated inspection tools are used to monitor product quality in real time. These devices identify defects, measure physical attributes, and ensure that products meet quality standards. Automated adjustments can be made to correct any deviations immediately, reducing scrap and waste.

- Statistical Process Control (SPC): SPC involves the use of electronic devices to collect and analyze process data for quality control. By monitoring key process variables and using statistical techniques, companies can detect variations in the process and take corrective actions before defective products are produced.

9. Integration with Digital Technologies

- IoT (Internet of Things): The integration of IoT technologies in industrial processes enables smart devices to communicate and collaborate across the factory floor. IoT sensors collect vast amounts of data, which can be used to improve efficiency, identify issues, and optimize processes.

- Industry 4.0 and Smart Manufacturing: With the advent of Industry 4.0, industrial electronic devices are becoming part of a connected ecosystem of machines, sensors, and controllers that interact with one another to enable autonomous operations and smarter decision-making. This trend is reshaping how industrial processes are managed, providing greater flexibility and scalability.

These devices, including PLCs, sensors, control systems, and safety systems, help improve the efficiency, reliability, and safety of industrial processes while reducing costs and enhancing product quality. Through advancements in digital technologies, such as IoT and smart manufacturing, industrial electronics continue to evolve, offering new opportunities for process improvements and innovation.