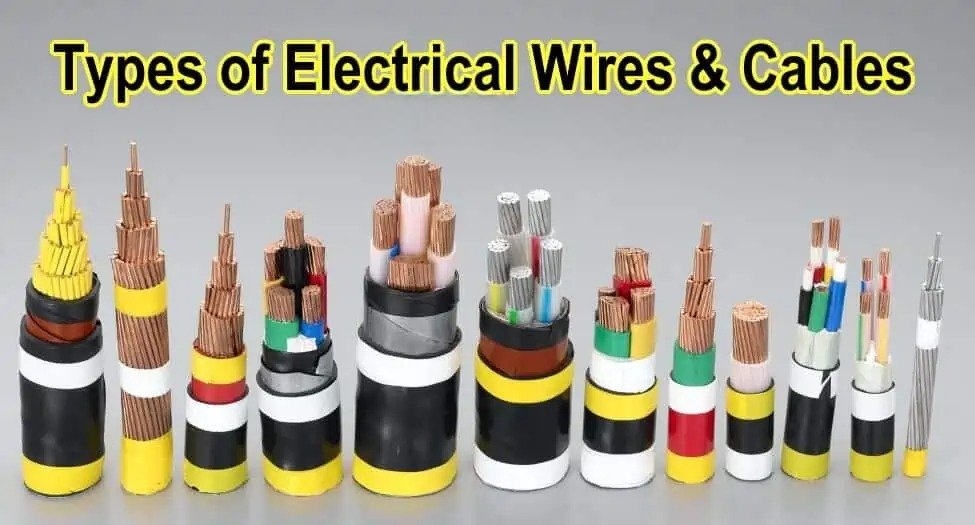

Electrical wires and cables are categorized based on their construction, usage, and environmental factors they need to withstand. The main distinctions include the type of conductor used (e.g., copper or aluminum), the insulation material, the voltage rating, and the specific application for which they are designed.

Here are the different types of electrical wires and cables, along with how they are categorized:

1. Based on Conductor Material:

- Copper Wires and Cables:

- Copper is a highly conductive material, making copper cables ideal for electrical transmission. They are widely used in residential, commercial, and industrial wiring systems due to their excellent conductivity, reliability, and flexibility.

- Advantages: Superior conductivity, resistance to corrosion, flexibility.

- Common Applications: Power distribution, appliances, electrical wiring in homes, offices, and factories.

- Aluminum Wires and Cables:

- Aluminum is less expensive and lighter than copper but has a lower conductivity. It is often used in long-distance power transmission and in situations where cost and weight are concerns.

- Advantages: Lightweight, cost-effective, suitable for long-distance transmission.

- Common Applications: Overhead power lines, large electrical systems, industrial settings.

2. Based on Insulation Material:

- PVC (Polyvinyl Chloride) Insulated Wires and Cables:

- PVC is one of the most commonly used materials for insulation in electrical wiring due to its durability, flame resistance, and cost-effectiveness.

- Advantages: Flame-resistant, durable, inexpensive.

- Common Applications: General residential, commercial, and industrial wiring.

- XLPE (Cross-Linked Polyethylene) Insulated Wires and Cables:

- XLPE is a more advanced insulation material compared to PVC, offering better heat resistance and higher durability, especially in high-temperature environments.

- Advantages: High-temperature resistance, long-lasting, ideal for heavy-duty applications.

- Common Applications: High-voltage cables, power transmission lines, industrial wiring.

- Rubber Insulated Wires:

- Rubber insulation is used for flexible cables, which need to withstand mechanical stress or bending.

- Advantages: Flexible, resistant to abrasion, suitable for outdoor and portable applications.

- Common Applications: Power tools, extension cords, portable generators, and heavy machinery.

- Teflon (PTFE) Insulated Wires:

- Teflon-coated wires are used in environments with high temperatures or chemical exposure.

- Advantages: High-temperature resistance, chemical resistance, durable.

- Common Applications: Aerospace, medical devices, industrial equipment exposed to chemicals.

3. Based on Voltage Rating:

- Low-Voltage Wires:

- These wires are used in circuits with a voltage of 0 to 750 V. They are used for general-purpose wiring in residential and commercial buildings.

- Common Applications: Household appliances, light fixtures, computers, and small electronic devices.

- Medium-Voltage Cables:

- Medium-voltage cables are used in systems with voltages ranging from 750 V to 33 kV.

- Common Applications: Distribution circuits in industrial plants, power distribution grids, and utilities.

- High-Voltage Cables:

- These cables are used to transmit high-voltage power (above 33 kV) over long distances.

- Common Applications: Power transmission lines, electrical substations, and power plants.

4. Based on Application Type:

- Power Cables:

- Power cables are designed for delivering electrical power to residential, commercial, and industrial systems.

- Common Applications: Power transmission, distribution, electrical installations, and power plants.

- Control Cables:

- These cables are used to carry signals that control electrical equipment or machinery, without transmitting electrical power.

- Common Applications: Industrial automation, machine control systems, electrical panels, and PLCs (programmable logic controllers).

- Communication Cables:

- These cables are designed for transmitting data and communication signals, such as in telephone systems, networking, and broadband applications.

- Common Applications: Networking (Ethernet cables), telephone lines, coaxial cables, and fiber-optic cables.

- Instrumentation Cables:

- Instrumentation cables are used in industries to carry signals from instruments and sensors.

- Common Applications: Process control systems, temperature sensors, pressure gauges, and other control instrumentation.

- Flexible Cables:

- Flexible cables are designed to bend and move without breaking, making them ideal for machinery or mobile applications.

- Common Applications: Industrial machines, robotics, portable power tools, and appliances.

- Submersible Cables:

- These cables are designed for underwater or submerged environments and are built to withstand water pressure and corrosion.

- Common Applications: Water pumps, mining operations, and underwater equipment.

5. Based on Construction and Protection:

- Armored Cables:

- These cables have an additional layer of protection, typically made from steel, to prevent physical damage. Armored cables are often used in areas with high mechanical stress or where additional safety is required.

- Advantages: Extra protection against impact, crush resistance, suitable for underground use.

- Common Applications: Industrial power systems, heavy-duty electrical wiring, and outdoor installations.

- Unarmored Cables:

- These cables are simpler in construction and do not have the extra protective layer found in armored cables. They are used in areas where the risk of physical damage is minimal.

- Common Applications: Residential wiring, light commercial use.

- Shielded Cables:

- Shielded cables have a layer of conductive material (usually copper or aluminum) around the insulation to protect the wires from electromagnetic interference (EMI) or radio frequency interference (RFI).

- Common Applications: Audio/video systems, data transmission, control systems in environments with high interference.

6. Specialized Cables:

- Fiber-Optic Cables:

- These cables use light signals rather than electrical signals to transmit data. They are made of glass or plastic fibers and provide high-speed data transmission with minimal signal loss.

- Advantages: High bandwidth, minimal signal loss, immune to electrical interference.

- Common Applications: Internet connections, telecommunications, and data centers.

- Coaxial Cables:

- Coaxial cables have a central conductor surrounded by insulation, a metallic shield, and an outer insulating layer. They are commonly used for transmitting high-frequency electrical signals.

- Common Applications: Television signal transmission, internet connectivity, and CCTV systems.

- Hybrid Cables:

- Hybrid cables are designed to carry both power and communication signals simultaneously. They are used in systems that require both types of signals to be transmitted.

- Common Applications: Solar power systems, telecom applications, and industrial automation systems.

Wires and cables are essential to the safe and efficient functioning of electrical systems. They are categorized based on their material, insulation, voltage rating, application type, and construction.