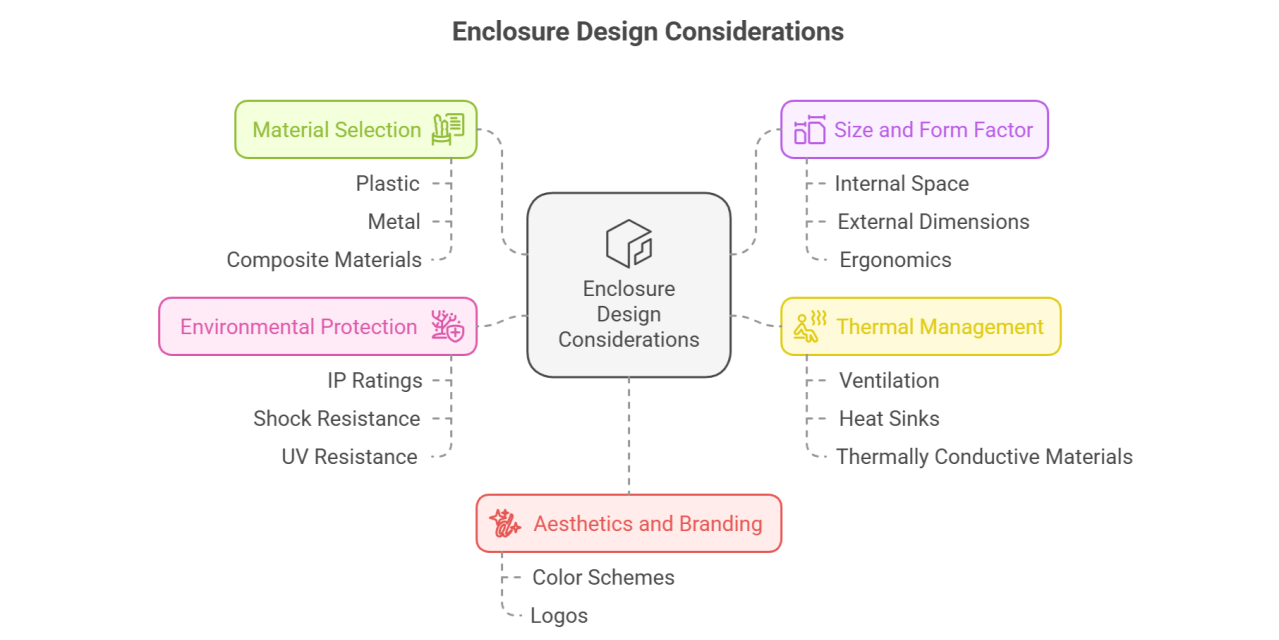

When selecting an electronic enclosure, several key design considerations must be taken into account to ensure the protection, functionality, and longevity of the internal components. Here are the most important factors to consider:

1. Size and Space Requirements

- Component Fit: The enclosure must have adequate space to accommodate all the components and wiring of the electronic system. This includes considering the dimensions of the printed circuit boards (PCBs), connectors, and power supplies, and allowing for easy installation and maintenance.

- Future Expansion: If future upgrades or expansions are anticipated, the enclosure should allow for additional space and flexibility for adding components or reconfiguring the internal layout.

2. Material Selection

- Environmental Protection: The material chosen for the enclosure should offer the appropriate level of protection against the specific environmental conditions the product will be exposed to, such as moisture, dust, chemicals, UV radiation, and extreme temperatures.

- For instance, plastic enclosures are lightweight, easy to mold, and often used for indoor environments, while metal enclosures (e.g., aluminum or stainless steel) offer superior protection in harsh environments, such as outdoor or industrial settings.

- Corrosion Resistance: If the product will be exposed to corrosive environments (e.g., saltwater, chemicals), selecting corrosion-resistant materials like stainless steel, or enclosures with protective coatings is essential.

- Thermal Conductivity: Some materials, like aluminum, are used for heat dissipation, while others like plastic may offer insulation. The material must be chosen based on whether the system generates significant heat that needs to be dissipated.

3. Ingress Protection (IP) Rating

- Sealing Against Dust and Water: The enclosure must be rated for ingress protection (IP) according to the level of dust and water exposure the system will face. Higher IP ratings (e.g., IP67, IP68) are required for outdoor or high-moisture environments, while lower ratings (e.g., IP40) may suffice for indoor applications.

- Gaskets and Seals: Ensure that the enclosure includes appropriate seals and gaskets to prevent the ingress of dust, water, or other harmful elements.

4. Ventilation and Cooling

- Heat Dissipation: If the electronic components generate heat, the enclosure must be designed for effective heat management. This could include using vented panels, heat sinks, or fans to allow airflow and prevent overheating.

- Thermal Management: Enclosures with built-in thermal management features like ventilation holes, cooling fins, or liquid cooling may be necessary for high-power or sensitive electronics that require consistent temperature control.

5. Mounting and Accessibility

- Ease of Mounting: The enclosure design should include mounting options that are compatible with the installation environment, whether it’s wall-mounted, rack-mounted, or freestanding.

- Access to Components: The enclosure should provide easy access for assembly, maintenance, and troubleshooting. Consider features like removable panels, hinged doors, or tool-less entry to allow for easy servicing.

- Cable Entry: Ensure that the enclosure includes provisions for cable entry and exit points, whether through grommets, cable glands, or entry holes, while maintaining the integrity of the seals and protection.

6. Electrical and EMI Shielding

- Electromagnetic Interference (EMI) Protection: For sensitive electronics, the enclosure may need to provide shielding against electromagnetic interference (EMI). This is particularly important for devices that operate in environments with a high level of electrical noise.

- Faraday Cage Effect: Metallic enclosures can provide shielding and block external electric fields, preventing the system from interference from external sources (e.g., radio frequency interference or static electricity).

7. Cost and Budget

- Material and Manufacturing Costs: The material and manufacturing process chosen for the enclosure should fit within the project budget. While metals like stainless steel may offer superior protection, they come at a higher cost compared to plastic enclosures.

- Cost-Efficiency vs. Protection: It’s important to balance cost-efficiency with the level of protection required. Choosing a basic enclosure for a sensitive system may lead to increased maintenance costs down the line.

8. Compliance with Standards and Certifications

- Industry Standards: Ensure that the enclosure complies with relevant industry standards, such as IP ratings for ingress protection, UL standards for safety, or RoHS (Restriction of Hazardous Substances) for environmental compliance.

- Certifications: Certain applications (e.g., industrial, medical, or hazardous locations) require enclosures to meet specific certifications like ATEX (for explosive atmospheres) or IECEx for explosive environments.

9. Aesthetic and Branding Considerations

- Design and Finish: The aesthetic of the enclosure may be important for consumer-facing products. The choice of color, shape, and surface finish (e.g., matte, gloss, textured) can influence the product’s appeal.

- Branding: The enclosure may need to include branding or labeling options, such as logos, product markings, or safety warnings, which should be incorporated into the design.

10. Durability and Impact Resistance

- Impact Protection: Enclosures in rugged or industrial environments must be able to withstand physical impacts. Materials like polycarbonate are often chosen for their impact resistance properties.

- Vibration Resistance: For devices operating in high-vibration environments, enclosures should be designed with vibration-dampening features or made from materials that offer resistance to such forces.

11. Environmental Impact and Sustainability

- Eco-Friendly Materials: Consider using materials that are recyclable or have a lower environmental impact, especially for products aimed at markets with strict sustainability regulations.

- Energy-Efficient Designs: Enclosures should be designed to optimize energy efficiency, whether through better heat management, lightweight construction, or the use of energy-efficient materials.

Conclusion:

Selecting the right electronic enclosure involves balancing functional requirements, environmental considerations, safety, and cost. Whether protecting sensitive equipment from moisture, heat, or EMI, or ensuring that the enclosure fits into a specific application, these design factors are crucial to ensure the proper performance and longevity of the enclosed electronics.

Hashtags

#MaterialChoiceForEnclosures #MetalVsPlasticEnclosures #CorrosionResistantMaterials #DurableEnclosureMaterials #WeatherproofEnclosureMaterials #LightweightEnclosures #IPRatedEnclosures #WaterproofEnclosures #DustproofEnclosures #IP65Protection #IP67RatedEnclosures #IngressProtectionForDevices #ThermalProtectionForEnclosures #HighTemperatureEnclosures #LowTemperatureResistantEnclosures #ClimateControlInEnclosures #EnvironmentalProtectionForElectronics #HumidityResistantEnclosures #ShockResistantEnclosures #VibrationProofEnclosures #ImpactProtectionForElectronics #DurableElectronicCases #RuggedEnclosuresForElectronics