Sensors play a crucial role in electronic liquid level controllers by detecting the liquid level within a tank or container and providing the necessary data to the controller for appropriate action. These sensors allow the system to monitor liquid levels in real-time, triggering alarms, pumps, or other mechanisms based on preset thresholds to ensure proper liquid management.

Here’s a breakdown of how sensors function within electronic liquid level controllers:

1. Types of Sensors Used in Liquid Level Controllers

There are several types of sensors used in electronic liquid level controllers, each with its specific applications and advantages:

- Float Sensors: These sensors use a float that rises and falls with the liquid level. As the liquid level increases or decreases, the float moves, activating a switch or sensor to signal the controller. This is one of the most common types of liquid level sensors, and it can be either mechanical (with a physical float) or electronic (using a magnetic float and reed switches).

- Capacitive Sensors: Capacitive sensors detect changes in capacitance caused by the liquid level. They are non-contact sensors that work by measuring the change in dielectric properties between the sensor and the liquid. These sensors can be used with various types of liquids and are known for their accuracy and reliability.

- Ultrasonic Sensors: Ultrasonic sensors use sound waves to detect the distance to the surface of the liquid. They emit ultrasonic waves, and by measuring the time it takes for the waves to bounce back, they can calculate the liquid’s distance from the sensor, thus determining the liquid level. These sensors are non-contact, making them suitable for applications where contact with the liquid is not possible or desirable.

- Radar Sensors: Similar to ultrasonic sensors, radar sensors use electromagnetic waves to detect liquid levels. They are highly accurate and can be used in extreme conditions (e.g., high pressure, temperature, or corrosive environments). Radar sensors are commonly used in industries where the liquid may contain impurities or when precise measurements are needed.

- Optical Sensors: Optical sensors detect changes in light reflection or transmission based on the liquid level. When the liquid covers or uncovers the sensor, it changes the amount of light reflected or transmitted, triggering a signal to the controller. These sensors are often used for point-level detection in clean or transparent liquids.

- Pressure Sensors: Pressure sensors measure the pressure exerted by the liquid at a specific point, which is directly related to the height of the liquid in the tank. They can be used to measure the liquid level in tanks and vessels and provide continuous level data to the controller. These sensors are often used for deep tanks or in applications where liquid densities vary.

2. How Liquid Level Sensors Work

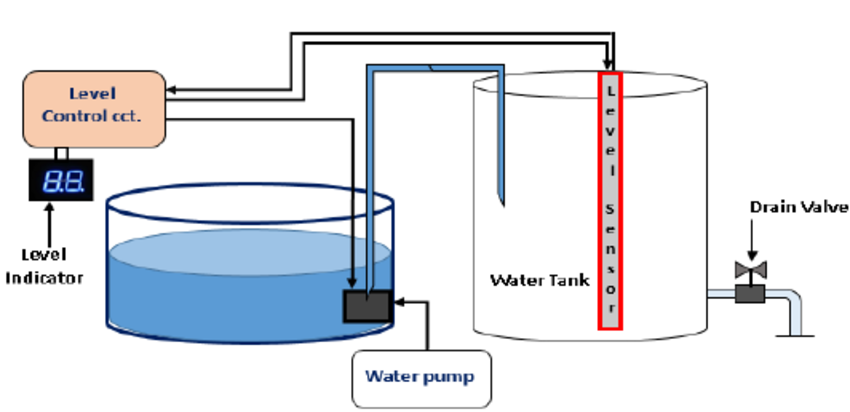

The fundamental function of sensors in electronic liquid level controllers is to detect the position or quantity of liquid in a container and relay that information to the controller. Here’s how this works:

- Measurement: Depending on the type of sensor used, the sensor either measures the distance between the liquid surface and the sensor (such as in ultrasonic and radar sensors) or detects a physical change (such as in float or capacitive sensors).

- Signal Generation: Once the sensor measures the liquid level, it generates an electrical signal, such as a voltage or current, corresponding to the liquid’s height. For example, a float sensor may generate a change in resistance or magnetic field strength as the float rises or falls with the liquid level.

- Signal Processing: The signal generated by the sensor is transmitted to the controller. The controller processes the signal to determine the exact liquid level. The signal may be analog or digital, depending on the sensor type.

- Decision Making and Action: Based on the liquid level reading, the controller makes decisions about the necessary action to take. For example, it might turn on a pump to fill the tank when the liquid level falls below a preset minimum or shut off the inflow when the tank reaches its maximum level. Alarms or visual indicators may also be activated when certain thresholds are crossed.

3. Role of Sensors in Maintaining System Accuracy

Sensors are critical for the accuracy and reliability of the electronic liquid level controller. The sensor’s precision in detecting liquid levels directly impacts the performance of the entire system. A high-quality sensor ensures that the controller receives accurate and real-time data, which leads to more reliable system operation and better control of the liquid levels.

4. Integration of Sensors with Controllers

Sensors in electronic liquid level controllers are often integrated with a central control unit or microcontroller. The microcontroller processes the signals received from the sensors and communicates with other components, such as pumps, valves, or alarms, based on the set liquid level parameters.

- Threshold Setting: The controller may be programmed to trigger actions when the liquid reaches certain threshold levels. For example, when the sensor detects that the liquid level has reached a preset minimum, the controller may start a pump to refill the tank. If the level exceeds the maximum threshold, the controller might shut off the inflow or activate an overflow alarm.

- Real-time Monitoring: Modern liquid level controllers often feature continuous real-time monitoring of liquid levels using sensors, ensuring that operators can access up-to-date data and make adjustments when necessary.

5. Benefits of Using Sensors in Liquid Level Control

- Increased Accuracy: Sensors provide precise measurements of liquid levels, enabling more accurate control of the liquid management system and reducing the chances of overflow or underflow.

- Automation: Sensors allow for automatic control of liquid levels, reducing the need for manual intervention and increasing operational efficiency.

- Safety: Sensors help prevent dangerous situations, such as overflows or dry running of pumps, by providing real-time data that triggers timely corrective actions.

- Remote Monitoring: Many sensors are connected to remote monitoring systems that allow operators to track liquid levels from a distance, which is particularly useful for hazardous environments.

6. Calibration and Maintenance

Sensors in electronic liquid level controllers require periodic calibration to maintain their accuracy. Calibration ensures that the sensor provides the correct readings relative to the actual liquid levels. Additionally, regular maintenance and cleaning of the sensors are necessary to prevent buildup or damage, which could impact their performance.

Conclusion

In electronic liquid level controllers, sensors are essential for detecting and measuring liquid levels in tanks, containers, or other vessels. They provide the necessary data to control systems, ensuring that liquids are managed effectively and safely. Sensors improve automation, accuracy, and reliability, while reducing human error and increasing operational safety in various industrial, commercial, and residential applications.

Hashtags

#LiquidLevelSensors #LevelSensorFunctionality #HowLiquidLevelSensorsWork #SensorBasedLevelControl #ElectronicLevelSensors #LiquidDetectionSensors #LevelControlWithSensors #SensorBasedLiquidMonitoring #CapacitiveLevelSensors #UltrasonicLevelSensors #ConductiveLevelSensors #OpticalLevelSensors #RadarLevelSensors #FloatSwitchSensors #InductiveLevelSensors #PressureLevelSensors #HighPrecisionSensors #AccurateLiquidLevelDetection #SensorAccuracy #PrecisionLevelControl #ReliableSensorTechnology #ExactLiquidLevelSensors